SUPER J pumps are API 675 positive displacement piston or diaphragm pumps for the dosing and injection of fluids.

- Output: up to 450 l/h, at 8 bar

- Pressures: up to 250 bar

- Flow adjustable from 0 to 100 % while running or stopped

- Maximum stroke length: 20 mm

- Maximum thrust: 500 daN

- Maximum motor rating: 0.75 kW

Mechanical reliability of the Super J pumps is ensured by the limited number of moving parts, which are generously sized. Readily accessible, these components are installed in dust- and splashproof housing for reduced maintenance costs.

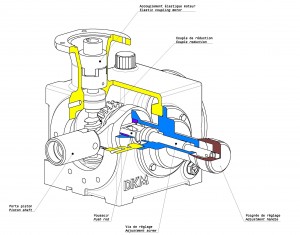

The wheel/screw pair driven by the motor actuates the connecting rod/crank system via an eccentric. The piston-carrier, attached to the pumping beam, performs an alternating linear movement. The operating rate depends on the rotational speed of the motor and the reduction torque ratio. The motor is mounted on an elastic coupling.

Flow Adjustment:

The flow rate of the Super J pumps is adjustable manually as standard by micrometric screw with a sealed dial graduated from 0 to 100 % of the maximum stroke. The adjustment is made by variation of the piston stroke. Accuracy is better than 1 % from 10 to 100 % of maximum output.

Control System:

Super J pumps are controlled by an electric servomotor, which adjusts the flow rate from 0 to 100 % according to the 4 to 20 mA control signal. Other options are possible with pneumatic servomotors and frequency variation motors, etc.

Multiplexing:

From 2 to 5 Super J plunger piston or diaphragm pump drive mechanisms may be combined.

Dosing Heads:

The Super J pump may be fitted with two types of dosing head:

– Plunger piston dosing head: for neutral products or for pressures up to 300 bar.

– Diaphragm dosing head: complete tightness, safety, total protection.